Brand Names

KO and Miyuki Beading Thread must be made by the same factory. The thread quality, spools, and colors are exactly the same. The labels are the only differences.

C-Lon and S-Lon or Superlon are also, as far as I know, made in the same factory for different producers. They may have yardage difference in the D size and C-Lon has 3 additional colors of the AA size. - More in post about C-Lon vs S-Lon

Thread Type & Construction

Nylon Monocord

Nylon was invented to replace silk for silk stocking. It is strong, can be pulled and has a bit of stretch. The original nylon stocking were so strong that they did not need to be replaced… and guess what, over time the quality was lowered on purpose so they would snag and need replacing… Back to nylon, the nylon filaments can be twisted into a 1-ply, 2-ply or 3-ply cord, or braided. C-Lon Bead Cord is a 3-ply bonded nylon. Chinese Knotting Cord is a braided nylon.

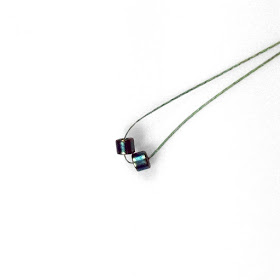

For the KO, Miyuki and C-Lon Beading Thread, the filaments are lightly twisted into a 1-ply cord, known as a monocord, not to be confused with monofilament, that's the original fishing line. In addition to its good abrasion resistance and excellent strength, the monocord has a flat, ribbon-like cross section and it flattens against beads making this type of thread great for doing multi pass through the bead holes. The thread is either waxed as in KO & Miyuki, or lightly bonded in the C-Lon Beading Thread to hold the filaments together. The multifilament monocord was originally designed as a low profile sewing thread.

Dyneema & Spectra

Both are Ultra High Molecular Weight PolyEthylenes. Dyneema is made by DSM in the Netherlands and Spectra by Honeywell in the USA. UHMWPE, for short, is know for its strength, low stretch and low weight. As a fiber, it is used for fishing lines, parachute cord, sailing lines, personal armor, puncture resistant clothing for fencing and more.

As to the differences between 6 lb. Fireline, 10 lb. WildFire and Power Pro, FireLine and Power Pro are braided whereas WildFire has a monocord thread construction. The 6 lb. Fireline has a thinner fiber braided core and a very thick thermally applied bonding. The bond material coats the fiber core, and the texture of the braid is non existent, whereas Power Pro has some texture, even through the bonded coat.

Thread Size or Diameter

Many beading techniques require multiple passes through the same bead hole, so the thread diameter is very important. The number on the chart represent the official diameters, but here is my list done by touch. The diameters are too thin to measure with a ruler or a caliper.

Thinnest to less thin:

1. KO - Miyuki Beading Thread

2. C-Lon Bead Thread Size AA ~ by just a tad, maybe…

----------------------------------------

3. C-Lon Bead Thread Size D

----------------------------------------

4. 6 lb. FireLine

5. WildFire 006

6. 10 lb. Power Pro ~ maybe by a tad, or the thread texture might makes the thread feel thicker…

I separated them in groups to delineate clear diameter size differences. Please note that FireLine, WildFire and Power Pro come in larger sizes, but they are a bit too thick to allow for multiple passes and they become harder to thread on the needles Size 10 or 12.

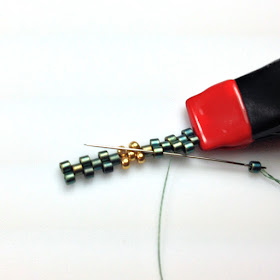

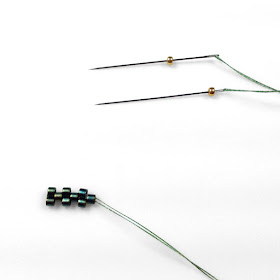

Ease of Threading onto a Needle

The thinner thread are easier to thread on a needle. I use beeswax at the end of the nylon thread to keep the filaments from separating. The hardest thread to insert into the needle are the braided ones, as they need to cut nice and clean and threaded immediately before the braid starts separating. PowerPro is the hardest one to thread into the needle, but once in, because of its texture, it stays in place, whereas the other threads, being more slippery, fall off the needle more easily.

Easier to Hardest to Cut

The nylon threads are easy to cut with sharp scissors. The Dyneema & Spectra thread are hard to cut, with FireLine being the easiest of the three, and PowerPro being the hardest. I tried regular embroidery scissors, wire cutters, and a thread burner, but that left a small bead at the end of the thread. A pair of titanium scissors worked best, especially when holding the thread taut when cutting.

Breaking Strength

See the chart, the thread lines up the following way, from lowest to highest:

4 lb. - 1.81 Kg - KO - Miyuki, C-Lon Bead Thread Size AA

----------------------------------------

6lb. - 2.72 Kg - 6 lb. FireLineC-Lon Bead Thread Size D

----------------------------------------

10 lb. - 4.53 Kg - WildFire 006, 10 lb. Power Pro

Colors and Notes on Thread

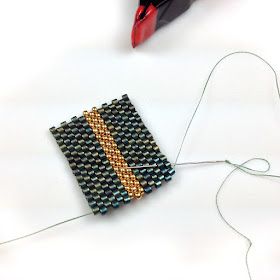

I have been told repetitively that with most beading techniques, the thread color does not show, but with peyote for example, the thread shows up on the edges… I can see it!

KO - Miyuki Beading Thread has 18 colors. Some of the colors are perfect. The Gold for example is absolutely perfect for gold seed beads. The Lilac, Denim, Light Grey, and Apricot are fabulous choices…

The thread is pre-waxed, making it easy to use. It is thin, easy to cut and threads easily onto a needle. The breaking strength is the lowest, but for pieces that are not structuraly under stress and for beads with smooth edges, it is very nice to work with. It flattens against the beads, making multiple passes easy as long as you hold the thread that is already in the beads taut while you insert the needle back in.

C-Lon Bead Thread Size AA & D come in 39 and 36 colors respectively. Many of the colors are amazing. I love the Light Brown, Purple, Chocolate, Grey, Burgundy, Seafoam, Turquoise & Teal, and it doubles up as a great thread for leather wrap bracelets/ladder bracelets especially in Size D.

Size D has a higher breaking strength and would be my first choice between the two. It functions very much like KO/Miyuki Beading Thread as to ease, especially with a light addition of beeswax. But stay away from low quality wax that is sticky. A good clean hard beeswax is what's needed here. Another thread conditioner option would be a light coat of Fray Block, not Fray Check that is too thick.

The colors on the nylon beading thread listed above are colorfast, washable, but may bleach with long exposure to sunlight. The Dyneema and Spectra beading thread listed below are basically white and cannot be dyed. The color is added to the bonding material. If you peel the bonded coat, the fiber underneath is white…

FireLine comes in two colors, Smoke and Crystal. Crystal is white. It seems a bit translucent, but when placed on a dark color, it does not change. Smoke is dark grey. The thread is quite strong, it can be pulled on and it will flatten somewhat against beads, but not as much as the nylon beading thread. FireLine and WildFire are fairly slippery, so watch the thread tension.

WildFire comes in 3 colors: Frost, Black and Camouflage Green. I nicknamed it Camouflage because the green seems to blend with many other colors somehow and it is also a color used in the military and for fishing…. For some strange reason I think I like WildFire better than FireLine, but that may be just this week…

And last but not least, Power Pro has just 2 colors. It has a few more colors, available in fishing stores, like a bright yellow, blue, red… but none have made it into the beading world yet, so try your local fishing store… This thread is strong and has a bit of a texture, so the needle does not fall off, but it also tends to stay rounder; it does not flatten much.

Consideration about Beads

The type of bead used is a major consideration. Check your beads, make sure that the bead edges are nice and smooth, or as smooth as possible. I found along the way that some beads are simply not suitable for cord and thread, and maybe not even wire. Some beads are simply not well cut enough to be used in any project. With natural materials such as gemstones, often the difference between an inexpensive strand and a more expensive one is the quality of the bead edges.With any beads that have a sharper edge, I would stay away from any of the nylon thread, as the sharp edges may abrade the filament one at a time. The heavy bonds on the Spectra and Dyneema thread will hold up better over time.

Structure or Drape?

I have read that drape or structure is based on the thread you use, but I have not found it to be the case. The thread tension is responsible for the drape or tight structure. In peyote stitch, for example, adding extra turns around beads can help hold the thread tension. It takes practice to hold the tension even. So yes, with your first piece, regardless of which thread you use, you may not have total control over the tension, but over time it gets easier.

Other Stress Factors

Consider what the end use will be and how much stress will be put on the piece you are making. In conventional jewelry, rings, for example, are considered more at risk than a pendant, bracelets somewhere in between… One should also consider how much pull there will be on the piece. If it is a bail, it will need to be able to hold up some weight and movement over time… So yes, the more stress, the higher breaking strength…

Personal Preferences

Some beaders are adamant about their preferences. For Peyote, I run into entrenched camp of FireLine vs PowerPro… I am still in the process of discovering and playing around. Color is a great consideration for me, and I have worked with C-Lon Bead Thread for a long time on leather wrap bracelet, so I am used to working with it. Cost is also a consideration as nylon beading thread is a lot less expensive than Spectra and Dyneema bonded thread. Well that is for another post… This one is already way too long!

–> Nylon Thread & Cord